Laboratory for dimension measurement techniques

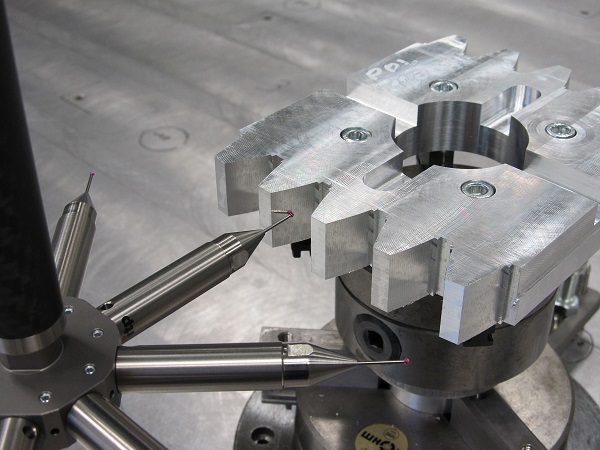

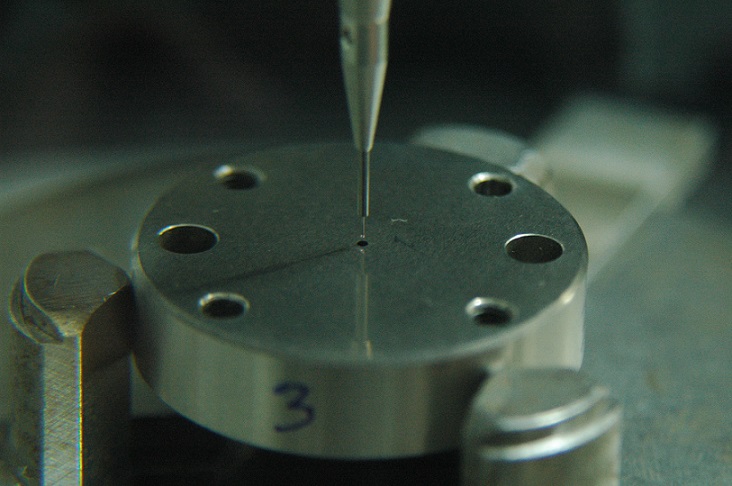

The BIMAQ analyzes shape, dimensional and positional deviations on components with dimensions of a few millimeters up to 3 meters. In addition to standardized measurement and evaluation methods for classical micro- and macro-geometric features, application-specific solutions are also developed, such as the determination of extended geometric features or the digitization of the 3D surface of complete components. Besides the application of known tactile sensors, a research focus is the realization, characterization and application of novel optical sensor and measurement systems including multi-sensor systems for fast and precise geometric measurements and quality control.

Research areas

- dimensional measurements on micro and macro geometries from µm to m

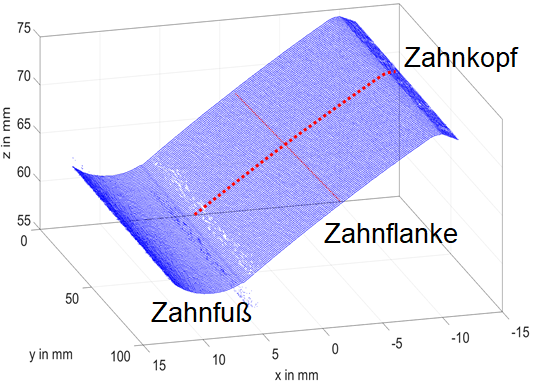

- optical 3D measurement of e.g. tooth flanks

- optical multi-sensor systems

- model-based determination of geometric characteristics (holistic approximation)

- microtopography and roughness measurements

- calibration of measurement systems and measurement uncertainty analyzes

- quality control systems based on geometric measurements

Measurement service

- order/reference measurements

- detection and analysis of geometric deviations - tactile or optically

- evaluation of surface quality - tactile or optically

- surface zone analysis - non-destructive and non-contact

- development of measurement and evaluation strategies

Equipment

chromatic confocal sensor Micro-Epsilon IFS2405-10

- measuring range: 10 mm

- light spot diameter: 16 µm

- resolution: 60 nm

laser-line triangulation sensor Micro-Epsilon LLT2900-25/BL

- measuring ranges: z-axis: 25 mm / x-axis: 25 mm (MBM)

- measuring points per profile: up to 1280

- reference resolution: 2 µm

- profile frequency: up to 300 Hz

stripe pattern projection system Steinbichler COMET5 1.4M

- resolution (measuring field): 40 µm (50 mm) / 350 µm (400 mm)

2-frequency interferometer Jenoptik ZLM 500

- measuring range distance/angle: 40 m / ±8° (up to 20 m length)

- resolution distance/angle: 2.5 nm / 1.25.10-7 rad

speckle sensors (in-house developments)

- measuring ranges (average roughness value, approx.): 20 nm - 2 µm

- measuring frequency: up to 100 Hz

portal coordinate measuring machine Leitz Reference 10.7.6

- measuring volume: 1.0 x 0.7 x 0.6 m³

- length measurement error: MPEE ≤ (0.9 + (L in mm)/350) µm

coordinate measuring machine Mahr Primar MX4

- measuring volume: 0.6 x 0.6 x 0.7 m³

- length measurement error: MPEE ≤ (1.2 + (L in mm)/500) µm

- rotary table: For rotation-symmetric components up to 0.6 m diameter

contour and roughness measuring device Mahr LD-120

- probe measuring range z/x: up to 20/120 mm

- resolution in z: 2 nm

- measuring point distance in x: min. 0.05 µm

- length measurement error: MPEE ≤ (1.0 + (L in mm)/100) µm

contour and roughness measuring device Mitutoyo C-5000

- probe measuring range z/x: up to 24/200 mm

- resolution in z: 4 nm

- resolution in x: 6 nm

- length measurement error: MPEE ≤ (0.3 + (L in mm)/500) µm

air conditioned measurement laboratory

measurement objects

- components and samples with dimensions from a few millimeters up to 3 m

- optical components (lenses, tools for manufacturing optical components)

- automotive body parts

- bearings and bearing components

- special components from the aerospace industry

Literature

A. von Freyberg, A. Fischer: Automatische Geometrie-Dekomposition von 3D Punktwolken. Sensoren und Messsysteme 2018 - 19. ITG-/GMA-Fachtagung, Nürnberg, 26.-27.6.2018, pp. 344-347.

A. von Freyberg, A. Agour, R. B. Bergmann, A. Fischer: Geometrische Auswertung digital holographischer Messungen im Bereich des Mikrokaltumformens. 8. Kolloquium Mikroproduktion, Bremen, 27.-28.11.2017, pp. 13-20.

Q. Wang, J. Miller, A. von Freyberg, N. Steffens, A. Fischer, G. Goch: Error mapping of rotary tables in 4-axis measuring devices using a ball plate artifact. CIRP Annals - Manufacturing Technology 67(1):559-562, 2018.

Contact Details

Axel von FreybergE-Mail: Phone:+49 (0)421 218 646 10