Laboratory for optical measurement techniques

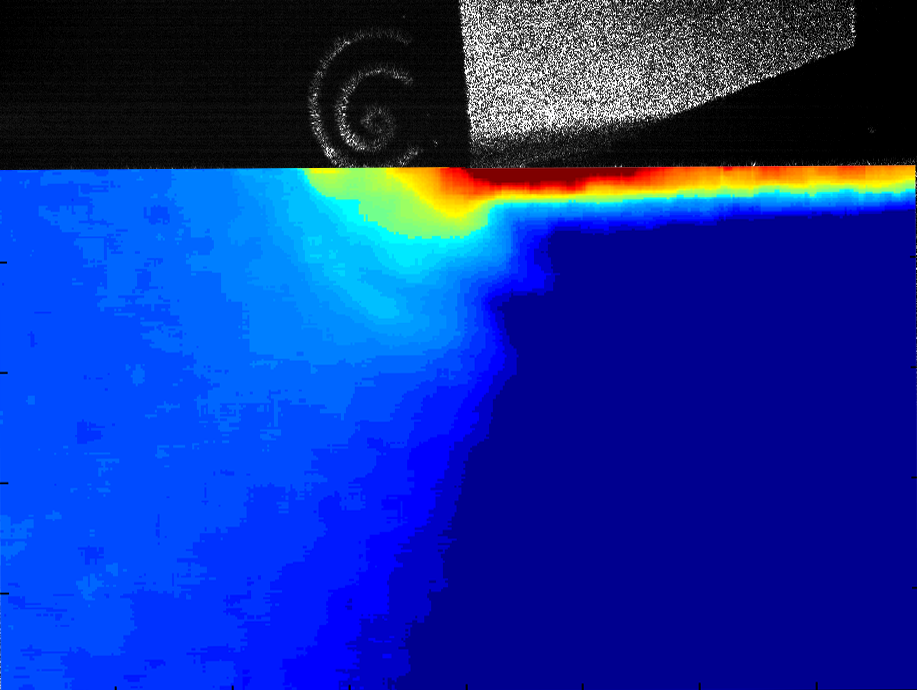

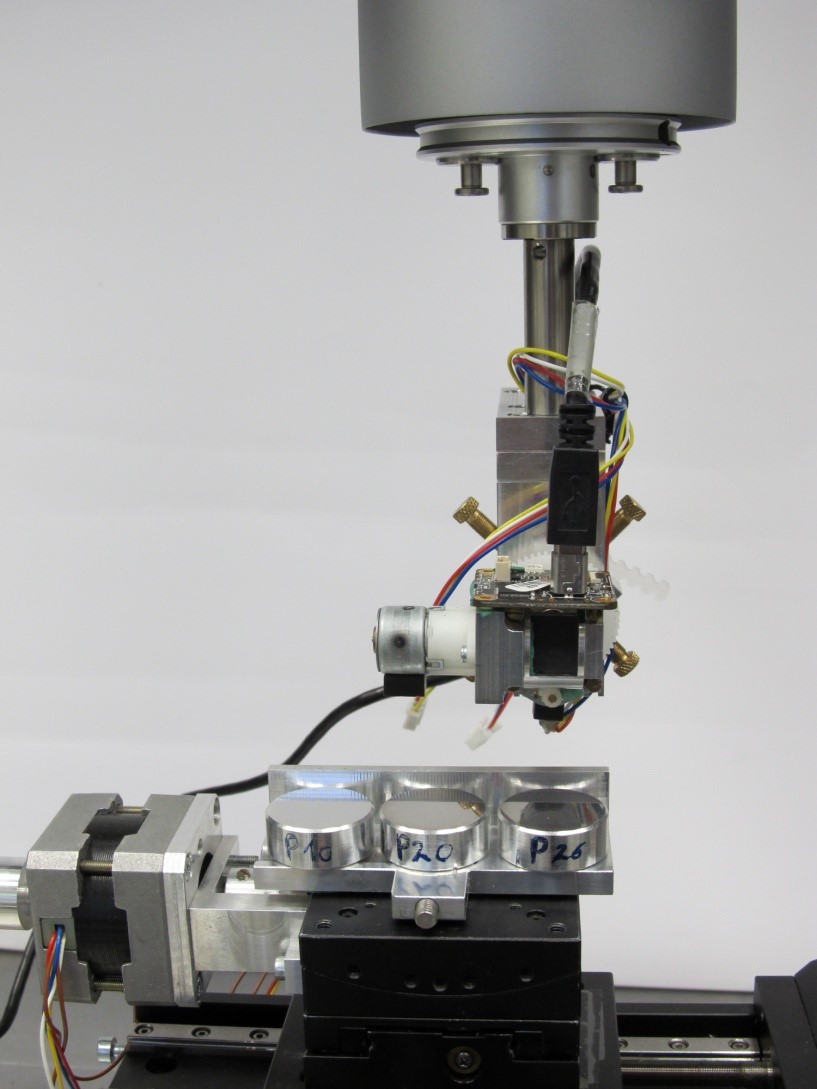

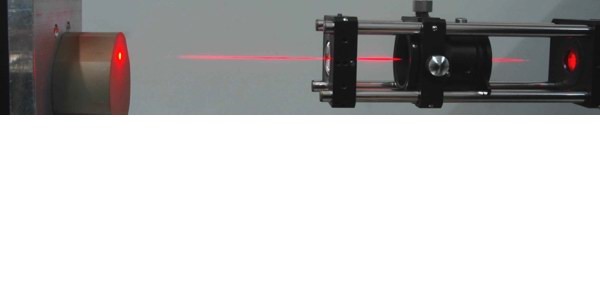

The process-near and in-process measuring technology represents an essential component for today's industrial production. This particularly applies against the background of the increasing expansion of interconnected manufacturing processes (Industry 4.0), which would not be able to control and optimize the individual processes and the process chain without the information determined in the process. Therefore, the BIMAQ is working on surface assessment by means of optical measuring methods. The main focus here is on scattered light methods, which, for example, allow statements about average roughness, structure heights and widths as well as defect classes of surface structures. Speckle photography is a research focus of the scattered light methods used to measure surface deformations and strains during component processing with deformation resolutions in the range of approx. 10 nm. In addition, also thermographic methods for deformation measurement and the white-light interferometry principle for process-related topography measurement are investigated. The goal is the realization of near-process and in-process measurement methods for various manufacturing processes, the characterization of measurement properties and the identification of fundamental limits of measurability.

Research areas

- measuring systems and evaluation methods for near-process or process-internal determination

- of (statistical) surface characteristics of micro- and nanostructured components

- of the locally resolved component deformation and/or the component load due to the process forces occurring during a machining or forming process

- contact pattern analysis of gears under load

- correction of systematic deviations of measurement methods

- uncertainty of measurement and fundamental limits of measurability

Measurement service

- feasibility studies for the application of measuring principles, especially in manufacturing and heat treatment processes

- development of measurement methods for concrete, industrial applications

- basic research for new in-process measurement methods

- simulation and measurement of light scattering on micro- and nanostructured components to assess structural quality

- non-destructive surface/topography testing by comparison with reference samples

Equipment

measurement systems

- various measuring devices for scattered light based surface characterization (in-house developments, measuring ranges: Roughness: 20 nm - 2 µm, measuring frequency: up to 100 Hz)

- speckle measuring systems for in-process deformation measurement of components (measuring frequency: up to 400,000 Hz, lateral resolution: ≈ 2 µm, deformation resolution: ≈ 60 nm)

- reference measuring system for high-resolution scattered light measurement (in-house development, angle range covered: almost 4π, angular resolution: 2 arc seconds)

- white light interferometer (Agos)

- 2-frequency interferometer (Jenoptik)

- tactile roughness measurement technology for comparative investigations (e.g. Mitutoyo CS5000, Mahr Perthometer, Mahr LD120)

- torque test bench for shafts and gears (Strama)

measurement objects

- prismatic, metallic components in the production processes grinding, turning, rolling, deep rolling

- nanostructured surfaces such as plastic and metal foils

Literature

G. Alexe, A. Tausendfreund, D. Stöbener, A. Fischer: Model-assisted measuring method for periodical sub-wavelength nanostructures. Applied Optics 57:92-101, 2018.

A. Tausendfreund, D. Stöbener, A. Fischer: Precise in-process strain measurements for the investigation of surface modification mechanisms. Journal of Manufacturing and Materials Processing 2(9):1-11, 2018.

A. Fischer: Fundamental uncertainty limit for speckle displacement measurements. Applied Optics 56:7013-7019, 2017.

S. Patzelt, C. Stehno, D. Stöbener, G. Ströbel, A. Fischer: In-Prozess-Charakterisierung spiegelnder Oberflächen mit Laserstreulicht und leistungsfähiger Hardware. tm – Technisches Messen 84(9):557-567, 2017.

Contact Details

Dirk StöbenerE-Mail: Phone:+49 (0)421 218 646 40